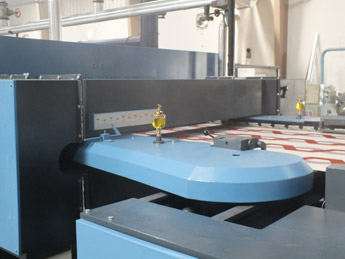

Storm Stenter

Salient Features

The Storm series of Hot Air Stenters have been designed keeping in mind the competitive environment our customers face. With emphasis on achieving higher processing speeds while keeping input costs minimal, this modular design outperforms those of our competitors heat setting machines on the following counts:

Higher Production Speeds

- Use of elongated oval Nozzle slits for higher air velocity

- Lowest gap between top and bottom Nozzle faces to prevent drop in enthalpy

- High energy blower fans to displace larger volumes of air

Efficiency

- Double jacketed sealed chambers providing dual insulation

- Seasoned cast iron lubricated rail providing friction free movement of chain

- All pipeline installed inside the chambers to cut out conduction losses

Maintenance

- Detachable Nozzle fingers for easy cleaning

- Online sliding filters for lint removal

- Easy access inside chambers for observation

Other than these features, the modular design provides for easy assembly and quicker commissioning, as well as, makes retrofits simple. We, at Harish Textile Machineries, adhere to strict quality standards, thus, our machines having minimal downtime, enabling our customers to have the maximum yield.